About Us

The Relentless Pursuit for Perfection

Yuh Chern Manufacturing Co., Ltd.

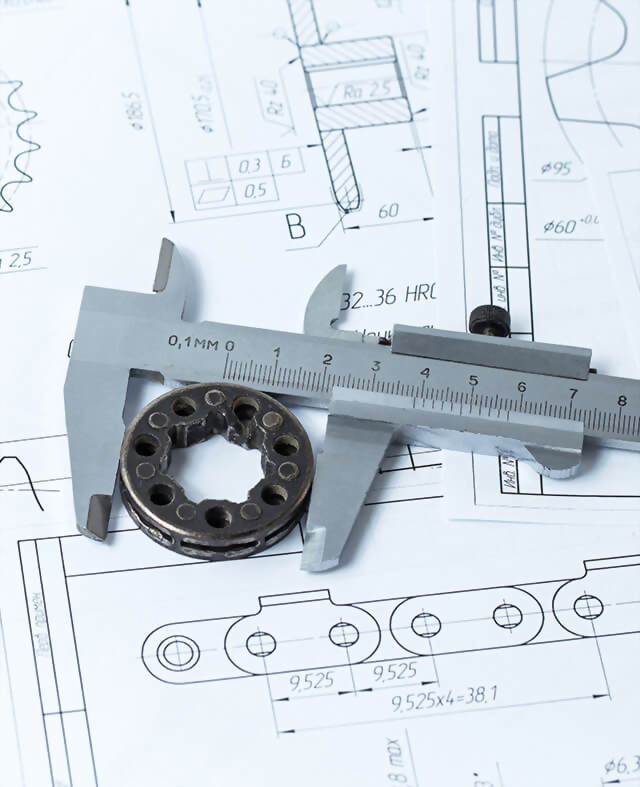

Yuh Chern Manufacturing Co., Ltd. was founded in

1979. The company is located in central Taiwan. We specialize in the

profession of hot forging technology and provide the best OEM services. The

evolution of company started with the production and distribution of conveyor

chains and accessories. Implementing flexible organization management and

continuously investing in facility machinery, we have progressively extended

our product capabilities and have entered other industries horizontally such

as the automobile and motorcycle parts, marine parts, and mountaineering

equipment componentry.

Following the company’s operating policy, the operational scale

and capabilities continues to increase. Alongside the continuous upgrading of

equipment, we use multiple professional control systems to enhance our

ability to provide market-leading solutions for our customers, such as:

ISO 9001 (Quality Management System)

PLM (Product Lifecycle Management)

APS (Advanced Planning and Scheduling System)

SFT (Shop Floor Tracking System)

ERP (Enterprise Resource Planning System)

Our focus on expanding the recruitment of professionals in the R&D,

marketing, and quality departments allows us to provide better products and

stable quality to fulfill the vision and mission of our company.

Integrity, Chariness & Responsibility

Be honest and

abide by organizational regulations and social norms. To fulfill and successfully achieve all promised work actions. Fully acknowledge one's responsibilities and requirements and have the ability

to take responsibility for one's own mistakes and failures. Don't blame

others and try to improve the problem.

Communication

Coordination & Teamwork

To

be organized and externalize ideas clearly. Acknowledge the necessity to ensure

that all involved are focused and of full understanding. To correctly

interpret, respond, and clarify the message conveyed has reached a consensus is

of most importance. Respect the

opinions from team members, support team decisions, and perform personal

responsibilities during work. Encourage members to actively participate in the

team and work together to achieve team goals.

Quality Oriented & Continuous Improvement

Actively follow the working

standard procedures, pay attention to details, use feedback mechanism to

identify quality problems and make improvements, and continuously improve work quality. Ability to use appropriate

methods to identify opportunities for improvement, develop action plans, and

take proactive actions to improve work conditions or processes.

Innovation Management Oriented &Striving for Superiority

Accept new work patterns with

an open mind, build a creative work environment, encourage others to break

through the status quo, and enhance the overall competitive advantage of the

organization. To be able to set challenging work

goals for oneself and achieve them, demanding high standards of work performance,

and constantly seeking breakthroughs.

Customer

Orientation & Service

Actions and plans need to focus on customer impact, proactively understanding customer needs and respond

quickly to provide customers with the information they need. This proactivity will help

organizations build long-term cooperative relationships with customers. Show enthusiasm to customers, effectively meet customer needs, solve

customer problems, and then improve customer satisfaction to win customers'

trust with quality & service.

Read More

Certification

integrate service

Company Quality Policy

Customer Satisfaction & Continuous Improvement

Company Vision

To further our knowledge and skill capabilities as

a service provider in the technical fields of forging,

stamping and machining

Company Mission

Through quality services and innovation, provide

our customers with the most trusted and technologically

advanced products

application

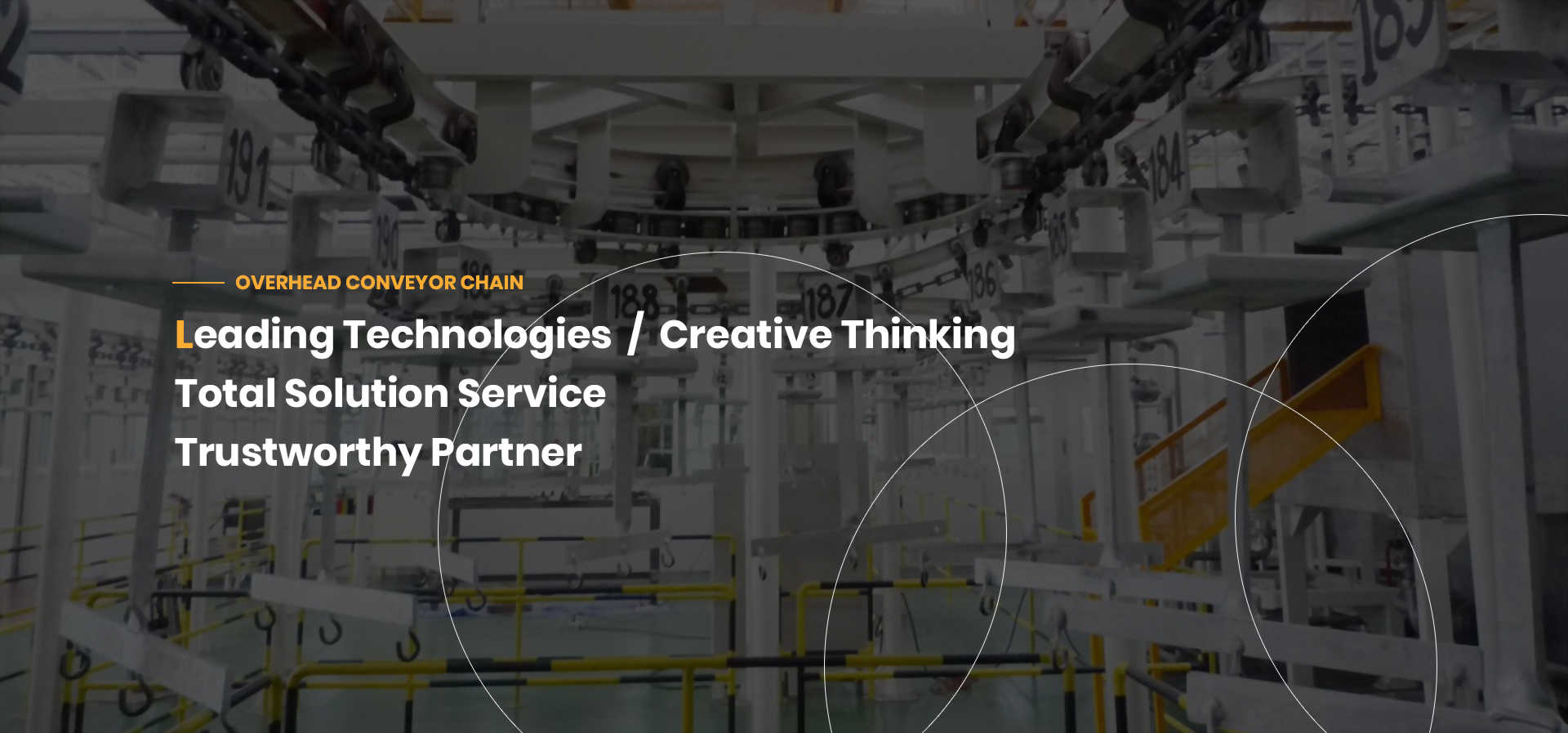

Conveyor Chains

The advantage of this system is that it can slide freely with in the smallest of bending radiuses in both horizontal and vertical motions. Bearings are used in this system to reduce the resistance in movement and increasing the system longevity...

Transportation Kits

Our excellence in product development has seen our production capabilities diversify into varies fields including the Transportation Industry. We have developed numerous after-market Motor Vehicle spare parts, Trailer parts such as Bearing Dust Caps, Wheel Bearing Protectors......

Customized Products

Our excellence in product development has seen our production capabilities diversify into varies fields including the Transportation Industry. We have developed numerous after-market Motor Vehicle spare parts, Trailer parts such as Bearing Dust Caps, Wheel Bearing Protectors......

Company Event

11

Feb

January New Product Announcing

New Product: LUG CHAIN ASSY

Process: Hot Forging & Stamping

Material: SAE4140 & S45C

Yuh Chern was founded in 1979 and has more than 40 years experience in the forging industry. In order to

provide customers with a more comprehensive service, we have integrated strategic manufacturing capabilities to provide OEM / ODM products and develop new products in various industries. Our services include forging, casting, CNC machining, metal stamping and assembly of final products to give clients high quality and professional care. Our technology services a variety of industries including; powder coating, food processing, sports, automotive, bicycle, household, and specific accessories in a wide range of applications and fields.

We continue to upgrade our equipment and enhance our ability to provide new advanced technological processes to realize our vision to become one of the world's best-integrated suppliers in the fields of forging, stamping and machining. We are committed to continue to diversify our product development skills into wider industries, such as mountaineering equipment, shipbuilding, sports equipment, construction parts (doors and windows) and other custom-made products.

In case of any further questions, please reach us! Thank you so much.

#chain#conveyor#forge#cast#part

30

Dec

December Company Event

2026 New Year Holiday Announcement

Dear Customers/Partners,

To welcome the New Year of 2026, our

company will be closed from January 1st (Thursday) to

January 4th (Sunday), 2026, and will

resume normal operations on January 5th (Monday).

We apologize for any inconvenience this

may cause during the holiday and thank you for

your understanding and support.

Wishing you a Happy New Year and all

the best!

Sincerely, The Company Team

08

Dec

November New Product Announcing

2025 November New Product Announcing

New Product: 7’ Bolt

Process: Zine plating

Material: S45C

Yuh Chern was founded in 1979 and has more than 40 years experience in the forging industry. In order to

provide customers with a more comprehensive service, we have integrated strategic manufacturing capabilities to provide OEM / ODM products and develop new products in various industries. Our services include forging, casting, CNC machining, metal stamping and assembly of final products to give clients high quality and professional care. Our technology services a variety of industries including; powder coating, food processing, sports, automotive, bicycle, household, and specific accessories in a wide range of applications and fields.

We continue to upgrade our equipment and enhance our ability to provide new advanced technological processes to realize our vision to become one of the world's best-integrated suppliers in the fields of forging, stamping and machining. We are committed to continue to diversify our product development skills into wider industries, such as mountaineering equipment, shipbuilding, sports equipment, construction parts (doors and windows) and other custom-made products.

In case of any further questions, please reach us! Thank you so much.

#chain#conveyor#forge#cast#part